Jump to Section:

When You Need Purity, Trust Our Products

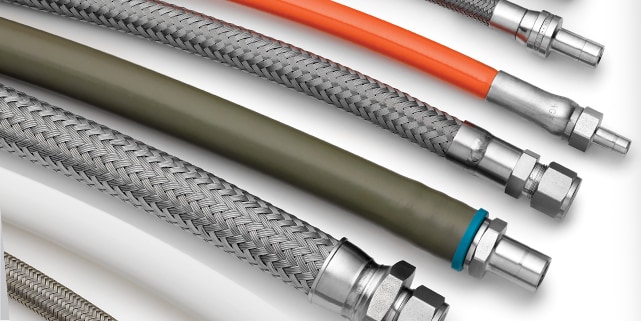

- Access a large portfolio of sanitary fluid system products, including tube fittings, ACME thread fittings, valves, and more

- Get prompt quotes and reliable delivery for special product fabrications, components, or skidded assemblies

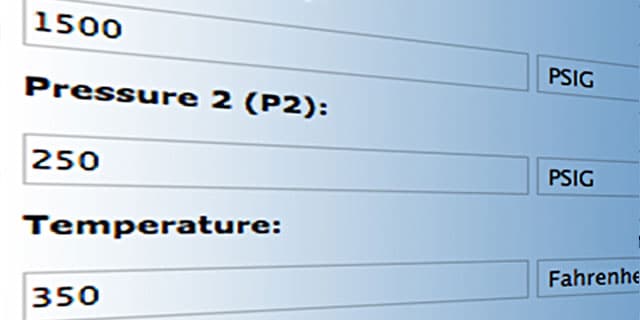

- Work with a supplier that continues to develop food-grade solutions that meet changing industry demands and higher pressure requirements, such as in the powdered milk sector

With more than 75 years of experience providing fluid system products and services across many industries subject to stringent oversight, we can help you reach your goals for process accuracy, workplace safety, and high sanitation levels.

Food and Beverage Applications

Our fluid system components support the preparation and packaging of food, beverage, and dairy products from meats and cheeses to sodas and sweets. We provide solutions to breweries, bakeries, and many other businesses that maintain critical unit operations, including:

- Baking

- Bottling

- Brewing

- Canning

- Cleaning

- Containment

- Distilling

- Milling

- Mixing

- Packaging

- Passivation

- Pasteurizing

- Preservation

- Processing

- Sterilization Storage

Products for Food and Beverage

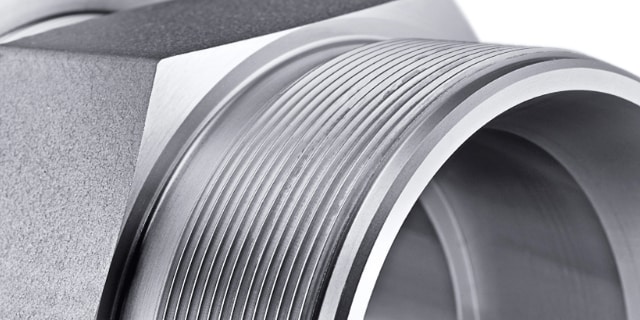

With fluid system products for virtually any application, Swagelok connects you to more choices that create process, safety, and cost benefits. We consult with food, beverage, and dairy plant engineers, as well as equipment builders, to develop standard and custom components that meet food-grade requirements and clean-in-place (CIP) and steam-in-place (SIP) standards, all backed by our Limited Lifetime Warranty.