North Sea Gas Field Operations Success

Total System Expertise: How Swagelok Delivered Assurance to a North Sea Gas Field

The Challenge: Developing a High-Stakes North Sea Gas Asset

The Challenge: Developing a High-Stakes North Sea Gas Asset

When a large European oil and gas operator based in the UK made the decision to develop a gas condensate field in the North Sea, expectations were high. Situated 250 kilometers east of Aberdeen, Scotland, this gas field was designed as an unmanned platform connected to a nearby processing asset.

In addition to the challenges of the volatile North Sea conditions, the site posed significant technical challenges as well. The wells were classified as ultra-high-pressure and high-temperature (uHPHT), producing corrosive gas streams that could include hydrogen sulfide. Safely containing and transporting gas demanded specialized alloys and precise installation. For the operator and its chosen engineering, procurement, and construction (EPC) contractor, this meant selecting project partners capable of not only delivering advanced materials but also of ensuring flawless execution in a highly complex environment.

The Approach: Leveraging a Global Swagelok Network

The specifications in the North Sea already included Swagelok products, and Swagelok Scotland | Teesside | Ireland had long-standing relationships with the operator. Swagelok Norway worked with the Norwegian EPC contractor, quoting and supplying the instrumentation scope, with Swagelok Scotland maintaining close alignment with the asset owner. Swagelok Denmark collaborated early with the design engineers on tubing specifications, and Swagelok Company provided coordination across territories, especially in formalizing oversight services and package vendor management. The specification quickly narrowed to two alloys capable of withstanding the gas field’s demanding conditions: Inconel 625 and super duplex stainless steel (SAF 2507). But more support was still needed.

Broadening the Scope: Transitioning from a Supplier to an On-Site Collaborator

As engineering advanced, Swagelok’s role expanded beyond product supply into installation oversight. In 2022, Swagelok Norway and Swagelok Scotland began discussions with the EPC contractor around training and inspection requirements. The operator mandated that all installers must have Engineering Construction Industry Training Board (ECITB) certification, and Swagelok supported the process, helping ensure compliance.

What started as two 10-day inspection assignments—one at a UK package vendor site and one at the fabrication yard in Norway—quickly evolved. Swagelok Scotland and Swagelok Norway then introduced their engineering project services and installation oversight programs. Embedding field engineers alongside the EPC contractor’s team delivered toolbox talks, installation guidance, and weekly storage audits. The scope expanded into continuous oversight, with Swagelok personnel on site for more than 40 weeks.

The Delivery: Swagelok Quality, Assurance, and Documentation

Swagelok’s comprehensive involvement delivered tangible outcomes to the operator and the EPC contractor:

- Zero punch list items: Through daily inspections and continuous oversight, Swagelok ensured that when the topside module left the yard, there were no tubing or fitting-related punch list items. This eliminated costly offshore rework and streamlined project handover.

- Comprehensive asset register: Swagelok Scotland leveraged its expertise in small-bore tubing systems to create a detailed asset register. Every P&ID line number was linked to precise part numbers for tubing, fittings, valves, and third-party instrumentation, providing superior traceability and simplifying future maintenance and asset management.

- Significant time savings: Oversight of installation, hydrostatic pressure testing, and system flushing activities resulted in a project schedule reduction of 6 to 8 weeks.

As Knut Marker, construction specialist of Swagelok Norway, put it, “By being present on site, inspecting, and documenting installations, we delivered a comprehensive engineering package that saved the customer time and money. In fact, the EPC contractor described our involvement as essential to the project’s success.”

Results: Enhancing Relationships and Fostering Customer Trust

By August 2025, the topside was completed for offshore installation. From zero tubing-related punch list items to reduced rework and increased efficiency during fabrication, Swagelok field engineers reassured both the EPC contractor and the operator that installations were correct the first time.

With Swagelok Scotland in a trusted advisory role within the project, Swagelok Norway handling technical and local delivery at the shipyard, and Swagelok Company supporting cross-border execution, work with the operator and EPC contractor was seamless. Success has already influenced customer expectations: the EPC contractor and the operator have expressed strong interest in adopting the installation oversight model on future projects.

Future Prospects: Setting an Example for the Oil and Gas Sector

For the operator, the EPC contractor, and the broader energy industry, the Swagelok North Sea Gas Project provided services beyond components, preventing errors and saving time.

As Marker emphasized, “This approach is relevant not only for offshore platforms but for any project where Swagelok products are installed. By following installations to site, inspecting, and reporting, Swagelok’s expertise extends beyond component supply to encompass oversight, assurance, and partnership at every stage of a project—from the North Sea to around the world.”

Gas Field Related Products

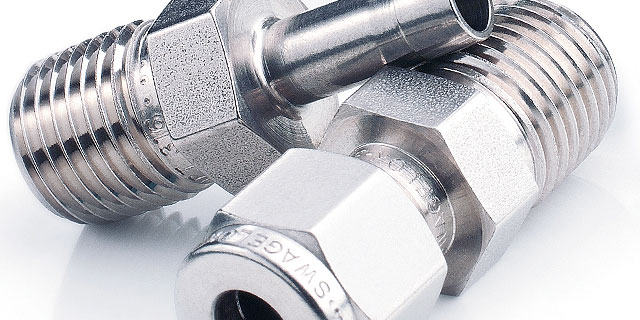

Fittings

Swagelok fittings meet strict quality standards through controlled processes, offering reliability for fluid system integration.

Valves

Delivering dependable, leak-tight performance in demanding industrial environments, Swagelok vales control flow under various pressures, temperatures, and conditions.

Tubing

Choose tubing with suitable material properties for your needs. Use accessories to cut, bend, deburr, and support tubing for leak-tight, durable systems.