Types of Valves and Valve Functions

Industrial Valves 101: Basic Functions and Types of Valves

Small-bore fluid systems play an important role in keeping industrial companies operating productively around the world, and valves play an important role in the function of these systems.

There are many types of valves that control flow in different ways, making it important for fluid system operators to understand both the types of valves available and different valve functions to make sure they can select the proper valves for their applications.

To make a proper valve selection, fluid system designers and operators need to consider questions such as, “Do I need to stop and start fluid flow? Do I need to control the direction of flow? Do I need to regulate flow level? Do I need to protect my system from overpressure?” The answer to these questions will dictate what types of valves are needed. From there, the designer or operator can work through more detailed valve selection considerations to ensure they choose valves with the proper size, materials, and performance criteria for their application (more on that at the end of this article).

In this post, we will explore the starting point of proper valve selection: understanding different types of valves used in industrial fluid systems so you can find the valve function needed for your applications.

Understand Valve Function Fundamentals

Understand Valve Function Fundamentals

What is a valve? A valve is a component designed to control the flow (i.e., continuous, steady movement) of liquids or gases to best suit the ideal operating conditions of a fluid system. This can be achieved by stopping, throttling, or redirecting that flow. As a liquid or gas flows, it moves from a higher pressure to a lower pressure. Typically, flow is measured by flowmeters, and is recorded in terms of a ratio of distance or volume per unit of time (e.g., meters per second, gallons per day, liters per minute, etc.).

How do valves work? Valves permit flow based on factors including the diameter of the valve’s end connection and the valve’s flow path. To help understand a valve’s ability to control flow, manufacturers typically provide a flow coefficient, or Cv, along with the supplied valve. A higher Cv means a higher flow rate, but a higher Cv is not necessarily beneficial. Depending on the valve type and application, some valves may come with a Cv of near zero. You can determine the Cv your valves need based on pressures, flow rates, temperatures, and media within your system by using our Cv calculator.

How are Valves Classified?

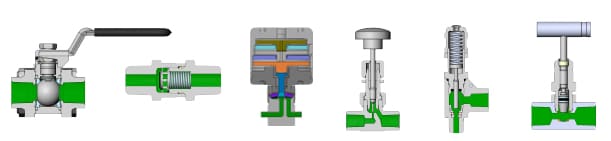

There are five main valve functions in industrial fluid systems that you should know: on/off, flow control, directional flow, overpressure protection, and excess flow control. Each type has an industry-standard symbol commonly found in piping and instrumentation diagrams (P&IDs). It is useful to understand both how valves are classified and their corresponding symbols so you can quickly draw connections between P&ID valve symbols and the function of the depicted types of valves.

-

On/Off. This is the most basic type of valve function. On/off valves start or stop the flow of fluid. Despite the basic nature of the valve function, there are many different types of on/off valves to choose from. Examples include:

- Ball valves: Ball valves provide reliable shutoff by using a handle to rotate a ball within the valve to block or allow the flow of fluid through the valve.

- Plug valves: Plug valves work similarly, minus the ball. They are operated using a handle that spins a plug within the valve to either block or allow fluid flow.

- Bellows valves: Bellows valves feature a taller cylindrical stem with an expanding and contracting bellows used to restrict flow to precise levels as a handle is spun, pressing an actuator onto the bellows.

- Diaphragm valves: Diaphragm valves operate similarly to bellows valves, but instead of an actuator constricting a bellows in the valve stem, the actuator presses down on a flexible diaphragm to restrict flow.

On/off valves can play a key role in maintaining fluid system safety. Many fluid processes operate at elevated pressures and temperatures and some fluids may be hazardous making it crucial to stop leaks to avoid risk to operators. Safety shut-off valves can help operators quickly cut off the flow of fluid in the event of a leak. You can recognize an on/off valve symbol (or ball valve sy) in P&IDs by its bowtie shape.

-

Flow control. These types of valves help adjust the flow through a system, providing functionality from simple flow regulation to fine metering. Needle valves are most commonly used to control or throttle flow. These valves are controlled by turning a handle to finely control an actuator inside the valve stem that ends in a needle that blocks flow through the valve as it is lowered.

Like a bellows or diaphragm valve, needle valves can provide on/off functionality, if necessary, but they are mainly intended to control flow rates. Those flow rates will be determined by orifice size, stem type, and stem position. As you can see, a flow control valve symbol (or needle valve symbol) in a P&ID is similar to an on/off valve, but with an extra downward-pointing triangle indicating the flow control functionality within the valve.

-

Directional flow. This valve function ensures that flow is headed in the desired direction, and these types of valves can change the direction of flow in the system. Check valves and multi-port ball valves are commonly used for directional control. Check valves prevent backflow, ensuring fluid continues flowing in only one direction. Mult-port ball valves can provide on-off functionality like other ball valves, but allow an operator to direct fluid flow in different directions based on the direction in which a handle is turned.

Importantly, while directional valves provide on/off functionality when changing flow, they do not throttle flow. You can recognize directional flow valve symbols (or check valve symbols) in P&IDs by looking for this icon showing a downward sloping arrow between two lines.

-

Overpressure protection. This valve function prevents system pressure buildup beyond a prescribed limit. Relief valves and rupture discs are the most common types of valves used here. Relief devices are highly important in any system that operates under pressure, acting as a last line of defense against overpressure conditions that could lead to a blowout. Relief valves can be calibrated to open automatically at a predetermined pressure level or gradually as pressure increases. Bleed valves

and purge valves are also used to bleed, vent, or drain fluid to allow safe maintenance or operation of fluid systems.

Overpressure protection valves can help safeguard your plant while allowing production to continue if overpressure happens. Recognize overpressure protection valve symbols (or relief valve symbols, etc.) in P&IDs by looking for this symbol with two intersecting triangles and an antenna-like structure above them.

-

Excess flow control. Excess flow valves can also have a role in system safety, helping contain uncontrolled release of system media by activating when flow through the valve increases to a predetermined value. Should an excess flow condition occur downstream, the valve’s poppet rapidly moves to the tripped or fully forward position, stopping most of the uncontrolled release of system media to minimize fluid escape. Excess flow valves then reset when pressure equalizes.

Excess flow valves eliminate the need for a complex bypass mechanism while reducing maintenance time. Excess flow control valve symbols are displayed in P&IDs with icons like this featuring a rectangle with constrictions on one side and a circle in the middle.

Learn to Select the Right Types of Valves

With a fuller understanding of flow and how different types of valves can help control it, you will be better equipped to make the proper selection in your fluid system design. This article, however, is just a primer. As a next step, consider reading more about using the proven STAMPED industrial valve selection method in this related article.

Alternatively, if you are interested in learning more about valve selection, identification, and troubleshooting, our Swagelok® Valve Essentials training is a great way to learn fundamentals. Beyond that, we also offer a variety of other courses taught by Swagelok-certified trainers focused on helping you develop the knowledge and techniques required to build and operate high-performing fluid systems. Learn more about available courses and topics at the link below.

Related Valve Articles

How to Select Valves for Industrial Fluid Systems

Learn how to apply the practical STAMPED method to select the valves most suited to your industrial fluid or sampling system design applications.

How to Improve Your Maintenance Program with Valve and Hose Tags

Hear from two Swagelok specialists how a robust tagging system for hoses and valves throughout your industrial fluid systems can help you simplify maintenance and minimize system downtime.

Your Guide to Valve Maintenance and Troubleshooting

Valves are critical to safe and reliable fluid system operation. Learn to maintain and troubleshoot valves in this guide.