Ensuring Reliable Operations, Backed by Proven Expertise and Global Support You Can Trust

Minimize downtime and maximize reliability with high-quality Swagelok fluid system components and engineered assemblies that meet the demanding needs of the Upstream segment, from exploration to drilling to production of crude oil and natural gas. Whether you are designing or working with offshore platforms, FPSOs, or subsea control systems, Swagelok supports these critical applications with oil and gas solutions designed for the unique challenges of your operations. In addition to high-performance products, Swagelok offers engineering services, installation oversight, and training to help upstream operators maximize safety, reliability, and efficiency.

Design Risk and System Standardization for Upstream Oil and Gas

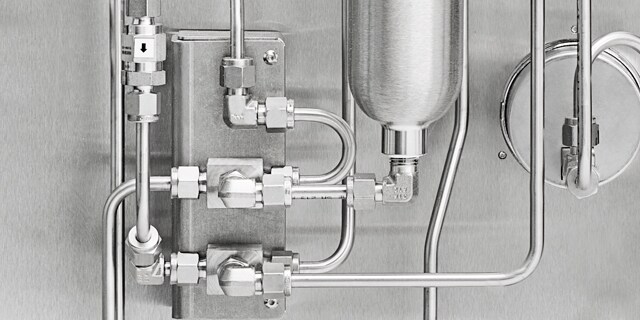

Operational environments in upstream oil and gas applications can be challenging. Extreme pressures, temperatures, and remote locations make design risk reduction and system standardization top priorities for safety and efficiency. Thanks to rigorous quality control throughout the manufacturing process, Swagelok products provide high-performance—consistently. Beyond fittings, valves and hoses, Swagelok solutions include standardized grab sample panels, gas distribution systems, mechanical seal support systems, and repeatable custom designs which simplify maintenance and improve ease of use.

High-Quality, Reliable Upstream Oil and Gas Solutions

Reliable, high-quality Swagelok components and solutions help simplify installation, maximize operational efficiency and minimize downtime, ensure safety and environmental compliance, and optimize the lifespan of equipment and assets. One such solution is the Swagelok® FK series medium pressure fitting, a modern alternative to cone-and-thread fittings, that offer vibration resistance and a leak-tight gas seal at pressures up to 20 000 psig.

Upstream Oil and Gas Installation and Commissioning

A leak-tight installation process during hookup and commissioning is critical for keeping your project on time. Our installation oversight is a preventive service that owner/operators can mandate to achieve enhanced project outcomes, increase quality and safety, and reduce cost and schedule overruns associated with substandard installation.

Upstream Oil and Gas Applications

FPSOs: Floating production, storage, and offloading vessels used in offshore operations to process, store, and offload hydrocarbons produced from subsea wells

Offshore platforms: Large structures built in bodies of water to support the exploration, drilling, and production of oil and natural gas from beneath the seabed

Subsea control systems: Underwater technologies used to remotely monitor and manage production equipment located on the seabed, such as wells, valves, and pipelines

Hydraulic systems: Use pressurized fluids to transmit power and control mechanical operations

Analytical and sampling systems: Setups used to collect and analyze fluid samples from oil and gas processes, ensuring accurate monitoring of system conditions and supporting safe, efficient operations

Instrument and control lines: Small-bore tubes or pipes that transmit signals or control fluids to operate and monitor equipment, such as valves and sensors

Fuel and lubrication systems: Setups that supply and manage fuel and lubricants to machinery and equipment, ensuring efficient operation and reducing wear

What Sets Swagelok Apart in Upstream Oil and Gas?

Global Strength and Local Expertise

Global Strength and Local Expertise

Wherever you are, you can count on the support of Swagelok experts who are well-versed in the critical considerations of upstream oil and gas projects. With more than 200 authorized sales and service center locations in approximately 70 countries, including in rapid-growth economies and near newly identified gas fields, Swagelok is here to keep your fluid system running smoothly. Your local sales and service team knows your culture, speaks your language, and understands regional needs. Plus, they are supported by Swagelok’s global manufacturing footprint and technical expertise that’s available around the world.

Superior Materials and Materials Expertise

Swagelok specifies stainless steel with a higher nickel and chromium content than minimally required by ASTM standards, and these optimized materials provide enhanced corrosion resistance. Products manufactured from advanced alloys such as alloy 2507, alloy 625, 6moly and others—can offer additional protection from general and localized corrosion, as well as stress corrosion and sour gas cracking. For the harshest environments, Swagelok offers products manufactured from NACE-certified materials.

With an expert-level understanding of metallurgy and compatibility, Swagelok materials scientists can help you find the right materials to meet any challenge. We can even help you control life-cycle costs by helping you choose an engineered combination of components comprised of different alloys that deliver an ideal balance of performance and cost-efficiency.

Oil and Gas Solutions

Swagelok fluid system specialists across the globe stand ready to help you make your operations safer, more efficient, and more cost effective.

Field engineers.

Whether it’s material recommendations, standardization of engineered systems, or efficient installation, Swagelok field engineers are available to collaborate with you. Field engineers can evaluate your critical systems to detect potential problems, optimize fluid and sampling systems, and advise on maintenance strategy. This team can also help you meet your decarbonization goals by identifying leak points in your systems, determining where energy is being wasted in your processes, and suggesting options like low-emissions valves or closed-loop grab sampling panels that help reduce fugitive emissions.

Design and assembly services.

Swagelok technical specialists create Custom Solutions ranging from simple fabricated assemblies and packages to full panels and enclosures. You benefit from reduced labor costs, reduced time to finished package construction, enhanced operational safety, and zero rework for critical assemblies. Swagelok will collaborate with you to determine the best solution. We can optimize your existing designs, provide configurable off-the-shelf designs, make specialized systems, or fully customize your build.

Fluid system training.

Whether your personnel are designing, installing, or maintaining critical upstream oil and gas fluid systems, we offer a training opportunity that will suit your needs. Having a properly trained team can help you stay on schedule, minimize rework, improve performance and design, and enhance safety across your assets. All courses combine classroom or virtual learning with practical, hands-on activities. Additionally, Swagelok provides a training specialized for offshore oil and gas applications.

Global support.

Swagelok has a team engineered to help ease the burdens associated with changing government regulations, varying operational standards, global coordination challenges, and extensive documentation requirements. From concept through commissioning, the Swagelok team is ready to assist.

- In the pre-FEED and FEED stages, our engineers consult on fluid system product selection and designs, assist with specifications, and recommend cost-saving configurations

- As the project proceeds, our team helps manage timelines and complex logistical issues, providing jobsite inventory and product availability throughout the project

- Swagelok can help coordinate multiple entities, provide customized or international contracts, offer clarity on government regulations, and help clear the way for on-time completion

Swagelok is your trusted partner for upstream oil and gas fluid system solutions. From concept to commissioning, our global team is ready to support your operations with expertise, reliability, and innovative products.

"(The customer) found that non-Swagelok assemblies had leakage after less than 10 remakes. The assemblies featuring Swagelok products were remade more than 20 times without leaks." — Jesper Skovning, field engineer for Swagelok Danmark