Swagelok Subsea Components: Reliable Solutions for Offshore Drilling Challenges

Protect Well Integrity with Swagelok Subsea Solutions

Drilling and subsea systems are at the heart of upstream oil and gas exploration and production. Offshore, subsea installations operate in some of the world’s most challenging environments—deep water, high pressure, and corrosive conditions. These systems are responsible for accessing, maintaining and producing hydrocarbons from beneath the seabed, requiring robust, reliable, and safe fluid system solutions.

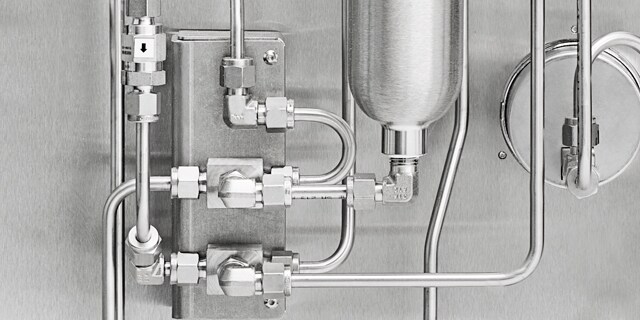

Swagelok understands the complexity of these operations. Our subsea solutions are engineered to support critical systems for offshore drilling and subsea skids, from wellhead control to hydraulic power units and chemical injection systems. We help operators protect well integrity through minimizing downtime, maximizing reliability, and ensuring compliance with global safety and environmental standards.

Drilling and Subsea Applications

- Offshore Drilling Platforms: Structures for exploration and production in deep water.

- Subsea Control Systems: Technologies for remote monitoring and management of underwater equipment.

- Hydraulic Power Units (HPUs): Powering well control and production systems.

- Chemical Injection Systems: Delivering chemicals to optimize production and protect equipment.

- Process and Analytical Instrumentation: Monitoring system conditions for safety and efficiency.

- Rotating Equipment: Supporting pumps, compressors, and turbines with reliable seal support systems.

Engineered for Subsea Performance

In subsea and offshore drilling environments, operators face persistent concerns about system longevity, unplanned maintenance, aging infrastructure, and the risk of costly interventions. Operators need assurance that every subsea component will perform reliably for years, even when exposed to saltwater, pressure cycling, and aggressive chemicals. Swagelok addresses these priorities by delivering solutions that help prevent leaks in critical control lines, simplify troubleshooting in complex hydraulic networks, and ensure compatibility with evolving industry standards.

Maintaining uptime in remote locations, where access for repairs is limited and every intervention can disrupt production, is critical. Swagelok’s offshore drilling solutions are designed to withstand the rigors of subsea environments:

- Extreme Pressure and Temperature: Our fittings, valves, and tubing are rated for high-pressure applications and maintain integrity across wide temperature ranges

- Corrosion Resistance: Advanced alloys such as 316 stainless steel, alloy 2507, alloy 625, and NACE-certified materials protect against saltwater, sour gas, and other corrosive agents

- Vibration and Mechanical Stress: Engineered for stability, our components reduce leak paths and resist failure caused by vibration and movement

- Ease of Use and Maintenance: Modular assemblies and standardized systems simplify installation and maintenance, even in hard-to-access subsea locations

Subsea Solutions for Critical Systems

For operators managing drilling and subsea systems, the stakes are high: every component must perform flawlessly to avoid costly downtime, environmental risks, and production delays. Whether it’s the ability to maintain system integrity during pressure surges, the challenge of sourcing components that meet stringent industry certifications, or the complexity of integrating new equipment into existing infrastructure.

With a focus on traceability, compliance, and long-term reliability, Swagelok empowers operators to overcome the most demanding offshore challenges—not only through our rigorously engineered subsea products, but also through a full suite of value-added services:

- Hydraulic Power Units (HPUs): Ensuring reliable fluid power for well control, blowout preventers, and production equipment in harsh offshore environments

- Subsea Control Modules: Achieving dependable remote monitoring and management of critical production equipment on the seabed, minimizing downtime and risk

- Chemical Injection Systems: Delivering chemicals efficiently to optimize production and protect equipment from corrosion and scaling.

- Process and Analytical Instrumentation: Maintaining accurate monitoring and sampling for process control and safety, even under extreme subsea conditions

- Instrument and Control Lines: Guaranteeing reliable signal transmission and equipment control using small-bore tubing and pipes, while preventing leaks and failures

- Rotating Equipment: Supporting pumps, compressors, and turbines with mechanical seal systems that withstand demanding subsea operations

- Standardized Assemblies: Reducing connection points, simplify maintenance, and improving ease of use with grab sample panels, gas distribution systems, and custom assemblies

Safety, Compliance, and Sustainability

Safety is non-negotiable in drilling and subsea operations. Swagelok’s offshore drilling solutions help you meet and exceed:

- JIP33, API and ASME specifications

- NACE and ASTM standards

- Environmental compliance for fugitive emissions

Our products are rigorously tested and backed by a limited lifetime warranty, giving you confidence in every connection. Swagelok also supports sustainability initiatives, helping operators reduce emissions, improve energy efficiency, and prepare for future fuels.

What Sets Swagelok Apart in Subsea Solutions?

Swagelok combines deep technical expertise with a truly global support network. Customers operating in remote, high-risk environments rely on Swagelok not just for products, but for partnership—knowing that our field engineers and technical specialists are available to collaborate on system design, troubleshoot complex challenges, and recommend best practices for installation and maintenance. Or that our materials science team can help select the right alloys and configurations to withstand the harshest subsea conditions, balancing long-term reliability with cost efficiency.

Beyond product quality, we understand the pressures of regulatory compliance, the need for traceability, and the importance of minimizing downtime. Whether you’re integrating new equipment, upgrading legacy systems, or preparing for future operational demands, Swagelok’s subsea services and solutions are designed to help you achieve your goals with confidence and efficiency.

Our commitment to responsive local service, backed by global resources, ensures that you have the support you need—wherever your operations take you.