Maximize Uptime with Swagelok FPSO Fluid System Expertise

In deepwater and remote drilling locations, floating production, storage, and offloading (FPSO) vessels are gaining momentum as a cost-effective, efficient alternative to fixed platforms especially for ultra-deep-water drilling.

Swagelok brings decades of experience in the oil and gas industry to the table and understands the issues that are top of mind for you when building, maintaining or retrofitting an FPSO vessel’s fluid system components. Whether it’s tight commissioning schedules that require on-time delivery and ongoing availability, or the need for safe, reliable, environmentally compliant systems with long-lasting performance, Swagelok is ready to help you make the most of your FPSO investment. Our team of experts provides technical consultation, logistics and supply chain resources, onsite support, and training for your FPSO construction project to ensure dependable operation in offshore environments.

How Will Swagelok Support You Throughout the Supply Chain?

Owner/Operator:

A global presence, breadth of products, and strong production volume help ensure products and support are readily available—maximizing uptime and safety while minimizing costs and environmental risks. Swagelok has a vast global inventory of products available at your needs.

Engineering, Procurement, and Construction (EPC):

Ensuring products comply with operator specifications and providing a single source of products, standardized training, and technical support enables smooth project execution. Swagelok supports EPCs by ensuring product compliance, offering standardized training, and providing technical support for seamless, on-time project execution.

Shipyard/Integrators:

Comprehensive project management support includes local experts that understand your needs, backed by global resources prepared to support international fluid system construction projects.

Package Vendors:

On-time, accurate delivery of products, training, and onsite services help keep projects on time.

Lean on Swagelok for support.

FPSO Installation and Commissioning

High-quality Swagelok components and solutions help maximize operational efficiency, reliability, and safety on an FPSO vessel and help ensure critical systems operate as designed. Plus, Swagelok custom design and assembly services, as well as fluid system training, can help keep your project on time by ensuring a simple, leak-tight installation process during hookup and commissioning that protects personnel and the environment while reducing costly downtime and repairs.

At Swagelok, materials science is a core competency. FPSOs operate in harsh environments, including exposure to saltwater, extreme temperatures, and corrosive conditions. Swagelok’s expertise in materials science ensures components withstand these challenges.

With Swagelok, you can be confident that the dependable components and solutions you need will be readily available. Swagelok is committed to on-time delivery and continued product availability at the local and global levels. Your most used products will be stocked locally for easy access. In addition, Swagelok holds inventory of thousands of standard products in regional warehouses, maintains a healthy stock of raw materials, and employs a global team of professionals who work with suppliers to ensure supply chain stability.

Topside Umbilical Termination Units (TUTUs)

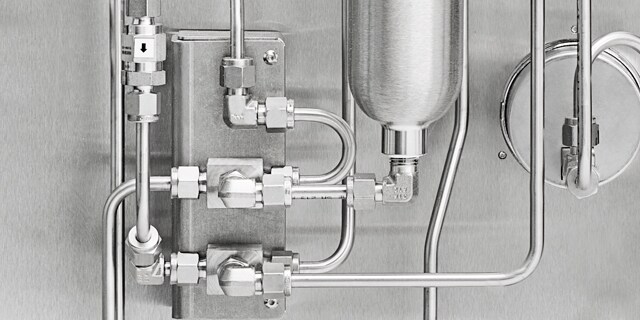

Serving as a connection point for the umbilical that runs from subsea equipment to the topside of the FPSO, topside umbilical termination units (TUTUs) require durable and corrosion resistant components. Leak-tight connections enable TUTUs to route essential services, control and monitor subsea systems, and provide safe isolation for maintenance activities. Select from readily available Swagelok components that meet your system parameters for pressure, flow, and fluid.

Hydraulic Power Units (HPUs)

Providing consistent power to topside, turret, and subsea production systems is critical on an FPSO vessel. Well-designed hydraulic power units (HPUs) built with trusted components ensure systems operate efficiently to avoid costly shutdowns, as well as safety and environmental risks. You can rely on high-quality Swagelok components, modular solutions, and capital project support to address your HPU system needs.

Chemical Injection (CI) Systems

Chemical injection (CI) systems precisely and repeatably deliver chemicals into the production well to optimize production. A CI system may be built with hundreds of components. Keeping the system leak-tight is critical for protecting personnel and the environment, as well as reducing downtime and production loss. Expertise in valves, fittings, and advanced services—including on-site inspection and installation verification performed by skilled field engineers—ensures optimal system performance and reliability.

Process and Analytical Instrumentation

Process and analytical instrumentation systems on an FPSO vessel may operate in harsh environments. Count on Swagelok to provide technical expertise and consultation to help you make suitable product and material choices for these systems. With a goal of minimizing rework during hookup and commissioning, as well as expensive maintenance and repair, our installation oversight services include training and competency management, onsite material management, technical support, inspection, and system flushing guidance.

Rotating Equipment

Reliable hydraulic, instrumentation, and safety systems are essential on an FPSO vessel. Systems may not only be operating at extreme pressures and temperatures but may also be exposed to corrosive conditions and vibration. Choosing Swagelok tubing instead of pipe can help reduce leak paths and ensure uptime. Plus, Swagelok offers a line of mechanical seal support systems designed to help keep pumps, compressors, and turbines, and other rotating equipment online—mitigating production shutdowns and profit losses. Mechanical seal support systems extend seal life by providing lubrication to seal faces, controlling pressure and temperature, flushing the seal of residue, and preventing system process fluid from leaking to atmosphere.

Grab Sampling Systems

A grab sampling system must deliver representative samples and allow operators to safely use the system, maintain chain of custody compliance, and make proper process control decisions. Determining the proper system requires technical expertise and an evaluation of the required sample pressure, temperature, phase, compatibility, and chemical composition to ensure the sample represents process conditions. Swagelok standardized grab sampling systems include local configuration, assembly, and support; optimized designs built according to best practices; clear labeling and easy operation; adaptability to meet system requirements; and assembly and testing by certified technicians.

Gas Distribution

Properly designed and installed gas distribution systems used in laboratories or critical production functions on an FPSO enhance efficiency and safety, while minimizing maintenance issues and related costs. Consider fully assembled and tested Swagelok gas distribution systems, which are available in four standard subsystem designs.

Which Swagelok products and services are available to support the fluid systems on your FPSO vessel?

| Chemical Injection Systems | Grab Sampling Systems | HPUs | TUTUs | |

| Tube Fittings | X | X | X | X |

| FK Series Medium-Pressure Fittings | X | X | X | X |

| FKB Series Ball Valves | X | X | X | |

| GB Series Full-Flow Ball Valves | X | |||

| Check Valves | X | X | X | X |

| Needle Valves | X | X | X | X |

| Grab Sample Panels | X | |||

| Medium- and High-Pressure Tubing | X | X | X | X |

| Global Construction Services | X | X | X | X |

| Design and Assembly Services | X | X | X | X |

| Fluid System Training | X | |||

| Hook-Up and Commissioning Service | X | X | X | X |

| Sampling System Evaluation and Advisory Services | X |

If you’d like additional support on your FPSO vessel project, consider engaging your local authorized Swagelok sales and service center.

Swagelok can help with your fluid system needs—starting at the pre-FEED and FEED stages consulting with owner companies and EPCs to assist with standardization and specification and makes recommendations for efficiencies and cost-saving configurations.

Throughout the project, the team is by your side to help you manage costs and support your objectives.